The countless machines, tools, and structures that form the backbone of modern industry owe their strength and durability to a single fundamental process: steel casting. This method, encountered wherever complex geometries, high strength, and longevity are required, involves shaping raw metal with artistic precision. At the heart of this process are steel casting molds, the key to success.

Ahkemak Metalurji has developed deep expertise in the casting industry since 1973 and has been practicing this art in its 4,000 m² modern facility in Konya since 2008. With half a century of experience, we experience the importance of steel casting and its molds in every project. So, how about learning more about this powerful industry solution?

What is Steel Casting? Why Is It Indispensable?

In its most basic definition, steel casting is the process of pouring molten steel into a mold that has the negative shape of the designed part, allowing it to solidify, and then removing it from the mold to achieve its final shape. This method allows for the production of complex and large parts in one run, which would be difficult or impossible to achieve with other manufacturing techniques such as forging or machining.

The key advantages of steel casting are:

- Design Flexibility: It offers engineers and designers virtually unlimited geometric freedom.

- Superior Mechanical Properties: Properties such as high tensile strength, toughness, and wear resistance make cast parts ideal for demanding environments.

- Material Diversity: A wide range of steel alloys can be used to meet the requirements of different applications.

- Cost Efficiency: It can be more economical than other methods, especially in mass production and for complex parts.

Thanks to these advantages, many critical industries, from defense and shipbuilding to the automotive and heavy machinery industries, derive their strength from steel castings.

Popular Alloys Used in Steel Casting

Steel is essentially an iron-carbon alloy. However, the addition of different alloying elements (chromium, nickel, molybdenum, manganese, etc.) radically alters the properties of the material. At Ahkemak Metallurgy, we determine the most suitable material for the project’s needs and then manufacture it. The most commonly used alloys in the industry are:

- Carbon Steels: They are classified as low, medium, and high carbon. They offer cost-effective solutions, especially in structural applications and general machinery parts.

- Alloy Steels: They come in types such as manganese and chrome-molybdenum. They are preferred for components such as gears, shafts, and crusher jaws, which require high strength, hardness, and wear resistance.

- Stainless Steels: Thanks to their high chromium content, they offer exceptional corrosion resistance. They are indispensable for the food, chemical, shipbuilding, and medical industries. Ahkemak Metallurgy, with its expertise in stainless steel casting, offers reliable solutions in this field as well.

- Other Casting Types: Depending on project requirements, various iron alloys such as gray cast iron and ductile iron are also used in a wide range of applications. Where It All

Where It All Began: What is a Steel Casting Mold?

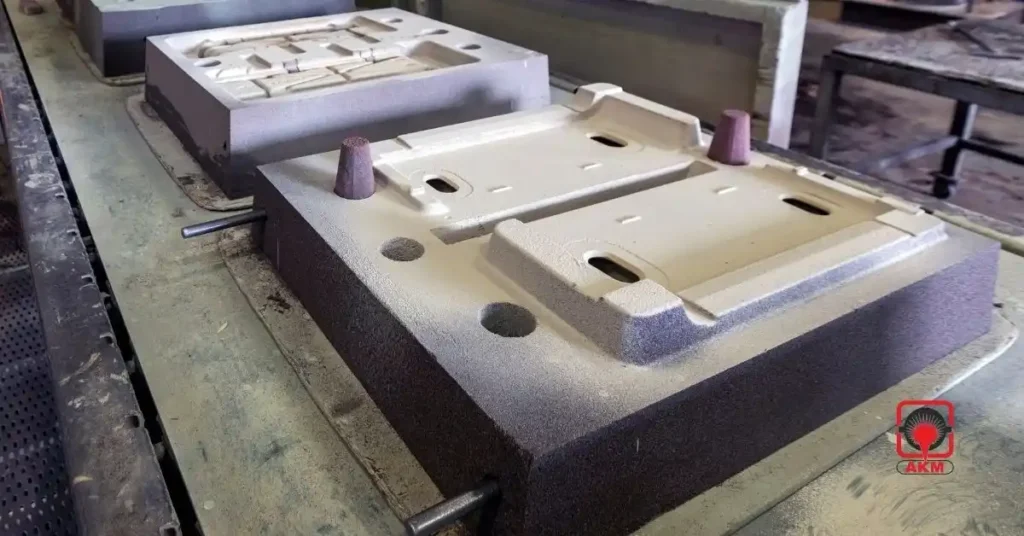

A steel casting mold is the structure containing the cavity (mold cavity) into which molten metal will be poured and where it will solidify to form the final product. The dimensional accuracy, surface finish, and internal structural integrity of a casting are directly dependent on the quality of the mold. The mold not only shapes the part but also helps achieve the desired metallurgical properties by allowing the metal to cool in a controlled manner.

Main Mold Types Used in Steel Casting

The selection of the mold type depends on many factors, including the number of parts to be produced, size, complexity, and desired surface finish.

- Sand Casting: This is the most common and versatile casting method. It is created by compressing a special mixture of sand and binder around a pattern. It is suitable for both small and large parts weighing many tons. Different techniques are available, such as green sand, dry sand, and resin-encrusted sand. Ahkemak Metalurji combines this traditional yet highly effective method with modern technology to achieve flexible and reliable production.

- Investment Casting (Ceramic Shell Molding): Also known as the “lost-wax technique.” First, a wax model is produced, which is then coated with a ceramic mortar. When fired, the wax melts and flows away, leaving behind a ceramic shell mold with extremely precise details. It is especially ideal for intricate, small, and smooth-surfaced aerospace and defense industry parts.

- Permanent Molds: These molds are typically made of iron or steel and can be used repeatedly. They are suitable for high-volume mass production and, because they allow for faster cooling, create a finer-grained internal structure.

Ahkemak Metallurgy: Half a Century of Assurance from Mold to Product

The success of a steel casting lies in the ability to combine accurate material knowledge, flawless molding techniques, and a meticulous quality control process. Drawing on its industrial heritage dating back to 1973 and the vision of its founder, Mehmet Ali Küçük, Ahkemak Metalurji combines these three elements in perfect harmony at its modern facilities in Konya.

The high-tech methods and detailed quality control measures we employ in our production processes are evident at every stage, from the initial mold design phase to the final heat treatment of the casting. We analyze our customers’ needs to determine the most suitable alloy and molding technique. We are proud to serve the most demanding sectors, from defense and transportation to machinery and shipbuilding.

With our innovative approach and commitment to continuous improvement, we transform every product emerging from our steel casting molds into a strong and reliable component of the industry. You can rely on Ahkemak Metalurji‘s deep-rooted experience to provide robust, durable, and precision casting solutions for your projects.

You can find our contact address via the link.

For more content, please visit our News page.