In heavy industries such as mining, construction, cement, and earthmoving, success in the field depends directly on the durability of the equipment. An excavator lifting tons of rock or a crusher subjected to constant friction will quickly lose its functionality if produced with standard materials. At this point, the relationship between steel casting and construction machinery gains strategic importance.

Standard steels fall short against the brutal conditions of heavy industry (abrasive wear, high impact, and shock loads). The result is frequent part replacements, unexpected machine downtime, and rapidly increasing operational costs. As Ahkemak Metallurgy, with our experience stretching from 1973 to today, we offer the definitive solution to this chronic problem: High alloy steel casting.

Wear in Heavy Industry: The Hidden Cost Monster

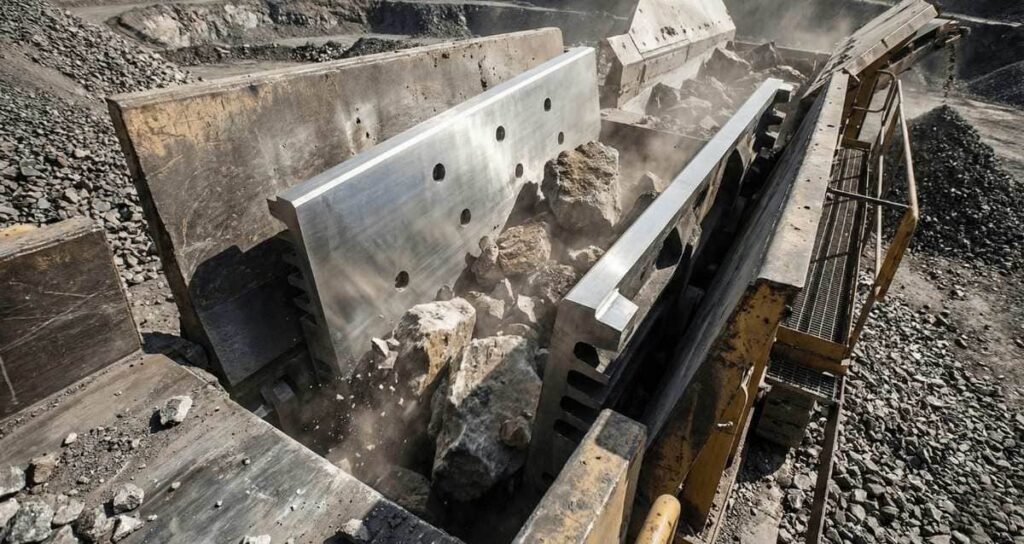

The biggest enemy of equipment used in heavy industry is wear. The wear of an excavator bucket tooth or a crusher jaw is not just the cost of that individual part. The real cost is the lost production and labor for every minute that machine is idle. Therefore, it is not enough for the parts chosen for construction machinery to be just “steel”; they must be reinforced with the right engineering and metallurgy.

Why High Alloy Steel Casting?

Steel casting is inherently a production method that offers high strength and toughness. However, when extreme wear is involved, standard steel casting alloys must be modified. This is where the concept of “high alloy” comes into play.

Ahkemak Metallurgy intervenes in the chemistry of the steel according to the environment in which the part will operate (e.g., high impact or intense friction?). High alloy steel casting, obtained by adding elements such as manganese, chromium, molybdenum, and nickel in the right proportions, performs significantly better than standard materials.

Advantages of Wear-Resistant Steel Casting

These steel casting parts, developed specifically for heavy conditions, provide businesses with the following tangible advantages:

- Long Service Life: They wear much slower than standard parts, extending replacement periods.

- Low Downtime Cost: The machine goes to service less and works more in the field.

- High Impact Resistance (Toughness): Especially manganese steels increase their surface hardness as they receive impacts, continuing to work without breaking.

- Decrease in Total Cost of Ownership: Although the initial purchase cost is higher than a standard part, it lowers the total cost thanks to its long life.

Critical Steel Casting Parts for Construction Machinery

Steel casting and construction machinery come together in the toughest tasks in the field. The main quality steel casting parts produced by Ahkemak Metallurgy in its modern facilities that bear the burden of heavy industry are:

- Crusher and Grinder Parts: Crusher jaws, impact crusher bars, mantles, and concaves. These parts work in intensely abrasive environments, and high chromium or manganese steel casting is generally preferred.

- Excavator and Loader Components: Bucket teeth, adapters, protective plates, and undercarriage parts. Both impact and friction resistance are of critical importance.

- Mining and Cement Equipment: Mill liners, grates, and chutes.

The Ahkemak Metallurgy Difference: Expertise and Technology

Casting a high alloy part is not just about melting the right elements. It requires a precise heat treatment process (quenching, tempering) and strict quality control.

In our 4000 m² modern facility in Konya, we combine our half-century of experience with technology. Every steel casting part we produce is prepared for the toughest conditions in the field by passing through spectrometer analyses, hardness tests, and non-destructive testing processes.

Wear is inevitable in the heavy industry and construction machinery sector, but the high costs caused by this wear are not. Extend the life of your equipment and increase your efficiency with Ahkemak Metallurgy‘s engineered high alloy steel casting solutions. Contact our expert team for your project-specific wear-resistant steel casting needs.

You can find our contact address via the link.

For more content, please visit our News page.